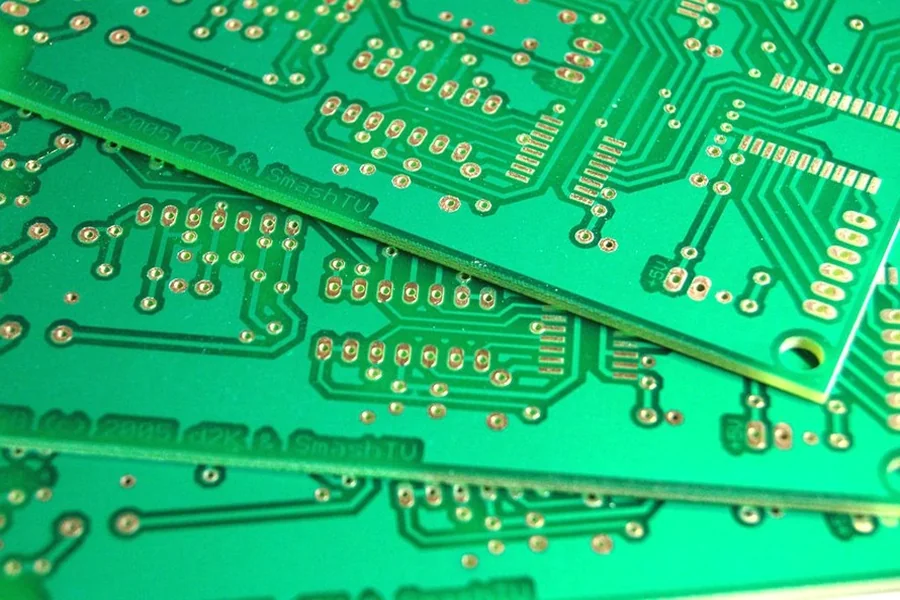

The 4 Layer Circuit Board is one of the most common types of multilayer printed circuit boards used in modern electronic devices. As technology continues to evolve, the demand for more compact, reliable, and high-performing circuits has increased, leading to a shift from simple single- and double-sided PCBs to multilayer designs. The 4-layer PCB strikes a balance between complexity and cost, offering a practical solution for devices that require more advanced circuitry without the expense of boards with six, eight, or more layers. It consists of four conductive copper layers stacked with insulating material in between, allowing for improved signal routing, reduced interference, and better performance in compact devices.

Structure of 4 Layer Circuit Board

The 4 Layer Circuit Board is built with a layered structure that includes two inner layers sandwiched between the top and bottom copper surfaces. These layers are separated by insulating dielectric materials, typically made from FR4 epoxy resin, and bonded together under heat and pressure to form a rigid structure. The outer layers are used for component placement and routing, while the inner layers are often dedicated to power planes and ground planes, which improve electrical performance by providing stable voltage levels and reducing noise. Vias, which are small plated holes, allow connections between these different layers, enabling complex designs that are not possible with single or double-sided PCBs.

Advantages of 4 Layer Circuit Board

The move to a 4 Layer Circuit Board brings several advantages that enhance both performance and design flexibility. By including additional inner layers, engineers can separate power and ground planes from signal traces, leading to reduced electromagnetic interference and improved signal integrity. This is especially important for devices that operate at high frequencies or require precise communication. Another major benefit is space optimization. With four conductive layers, circuit designers can achieve greater routing density without increasing the board’s physical size, making it ideal for compact devices such as smartphones, medical instruments, and industrial control systems. Heat dissipation is also more effective in multilayer designs, as power distribution can be managed more efficiently across the inner layers.

Applications of 4 Layer Circuit Board

The 4 Layer Circuit Board is widely used in industries where reliability, compact size, and advanced performance are required. In consumer electronics, they are commonly found in smartphones, tablets, laptops, and gaming consoles, where space is limited but circuit complexity is high. In the medical field, 4-layer PCBs are used in diagnostic equipment, monitoring devices, and imaging systems that demand precision and stability. The automotive industry relies on these boards for engine control units, infotainment systems, and safety electronics that must function reliably under harsh conditions. Telecommunications and networking equipment also make extensive use of 4-layer PCBs to manage high-speed data transmission while maintaining signal integrity. The ability of these boards to handle moderate complexity at a reasonable cost makes them one of the most versatile PCB types available today.

Limitations of 4 Layer Circuit Board

Although the 4 Layer Circuit Board offers numerous benefits, it also comes with certain limitations. The manufacturing process is more complex than single or double-sided boards, which results in higher costs and longer production times. While they provide sufficient routing capacity for many applications, they may not be adequate for extremely complex circuits that require higher layer counts, such as advanced computing systems, aerospace electronics, or next-generation communication infrastructure. Designing these boards also requires greater expertise to ensure proper layer stack-up, impedance control, and thermal management. Despite these challenges, the advantages of 4-layer boards often outweigh their drawbacks, particularly for mid-level applications where cost, size, and performance must be carefully balanced.

Why 4 Layer Circuit Boards Are Important in Modern Electronics

The significance of the 4 Layer Circuit Board lies in its ability to deliver reliable electrical performance while supporting compact, high-functioning designs. With the continuous trend toward miniaturization and higher processing speeds, devices cannot rely on single or double-sided boards alone. The 4-layer structure provides a practical middle ground, offering better performance without the cost and complexity of boards with many more layers. Advances in PCB manufacturing have also improved the quality of 4-layer boards, ensuring greater durability, enhanced thermal stability, and compatibility with lead-free soldering and other environmentally friendly processes. For industries seeking to stay competitive, incorporating 4-layer PCBs into product design is often a necessary step toward achieving innovation and reliability.

Conclusion

The 4 Layer Circuit Board represents a crucial advancement in PCB technology, offering a perfect balance between cost and performance for modern electronic applications. With its ability to support higher circuit density, reduce noise, and enhance electrical performance, it has become a preferred choice across industries such as consumer electronics, automotive, medical, and telecommunications. While it may not be suitable for the most complex systems, it continues to provide a highly effective solution for mid-range designs where efficiency and reliability are essential. For companies looking to integrate this technology into their products, working with a trusted 4 Layer Circuit Board Manufacturer ensures access to high-quality boards that meet demanding performance requirements while remaining cost-effective.